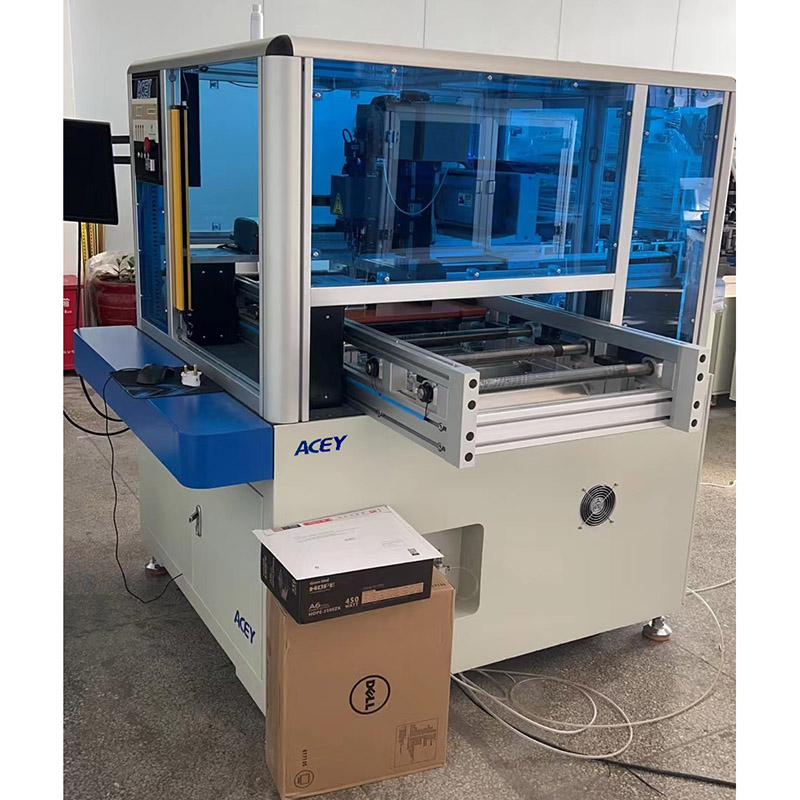

Ultrasonic Wedge Wire Bonding Machine For Battery Pack Welding

Description

ACEY-3753A is the first automatic ultrasonic thick aluminum wire welding machine in the country to use the rotary welding head method. It adopts a digital automatic frequency tracking ultrasonic system, a digitally controlled pressure adjustment function, a first-class image recognition device, and a fully closed loop motion control circuit. Realize the full automation of China's thick aluminum wire bonding machine.

Features

*Adopt advanced image recognition technology and automatic positioning technology to realize automatic and accurate positioning of solder joints.

*The powerful and abundant digital ultrasonic ensures stable and reliable solder joint quality.

*Automatic frequency tracking ultrasonic system and reasonable welding head design ensure the quality of welding joints.

*The original digital pressure control system ensures constant pressure output to ensure the consistency of solder joints.

*Precision mechanical transmission mechanism, reliable industrial computer and software with independent intellectual property rights ensure the accuracy of welding position.

*It has multiple fault alarm and shutdown functions such as a welding failure, abnormal wire setting, etc., which greatly reduces the rate of defective products and greatly improves the output. It is more maneuverable and user-friendly.

Specification

|

Power supply |

220VAC±10%, 50Hz 1200W |

|

Ultrasonic power |

0~30W |

|

Weldable aluminum wire diameter |

125~ 500um (5~20mil) |

|

Working area(XY axis maximum) |

400×400mm (can be customized) |

|

Z axis |

100mm. C axis: plus or minus 180° |

|

Ultrasound time |

10~500ms, multi-channel |

|

Welding pressure |

50~1200g, multi-channel |

|

Welding angle |

±90 degrees |

|

Vision system |

PR microscope magnification is 0.5 times |

|

PR lighting |

white light, adjustable brightness |

|

Dimensions |

about 1500*2200*1650mm(L*W*H) |

|

Weight |

about 800KG |

Product Display

Bronze supplier

Bronze supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram