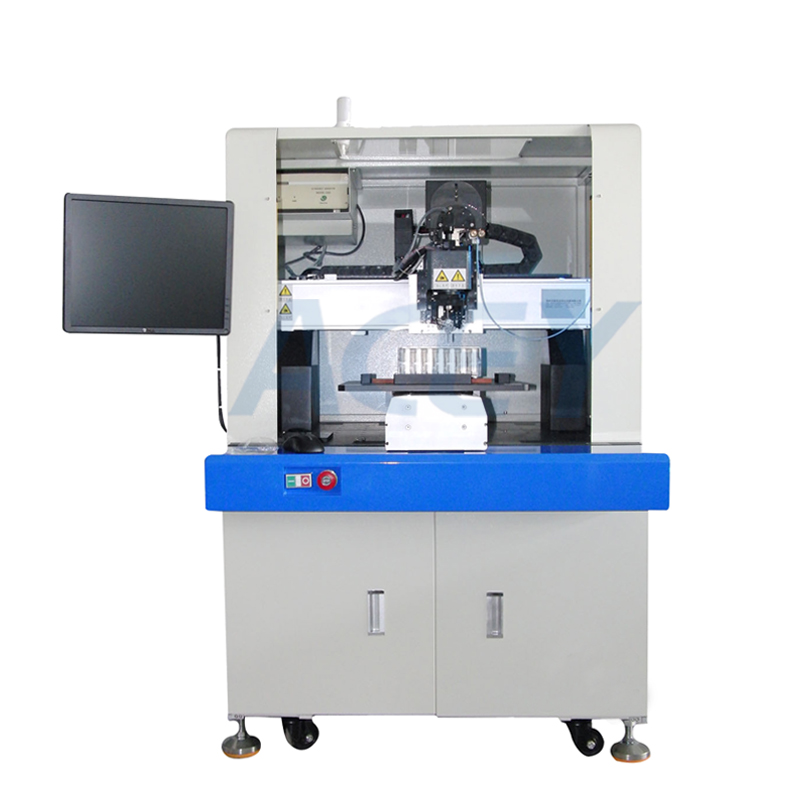

Lithium Battery Pack Aluminum Wire Bonding Machine

Wire Bonding Working Principle

After the module assembly process is completed, it is loaded by the automatic feeding system of the equipment, and then transferred to the welding area through the automatic feeding system, and the welding head system performs ultrasonic welding according to the set welding parameters and positions. After the welding is completed the module is transferred to the designated position through the automatic feeding system, and the equipment operator takes the welded module away and sends it to a next production process processing

Specification

|

Power supply |

220VAC±10%, 50Hz 800W |

|

Ultrasonic frequency |

60KHz |

|

Ultrasonic power |

0~30W |

|

Weldable aluminum wire diameter |

125~ 500um (5~20mil) |

|

Working area(XY axis maximum) |

400×400mm (can be customized) |

|

Z axis |

50mm. C axis: plus or minus 90° |

|

Ultrasound time |

10~500ms, multi-channel |

|

Welding pressure |

50~1000g, multi-channel |

|

Welding speed |

about each wire/1.5 seconds |

|

Welding angle |

±90 degrees |

|

Vision system |

PR microscope magnification is 0.5 times |

|

PR lighting |

white light, adjustable brightness |

|

Dimensions |

about 964mm*1215mm*1525mm (L*W*H) |

|

Weight |

about 400KG |

Wire Bonding Technological Process

Product Display

Related Products

Bronze supplier

Bronze supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram