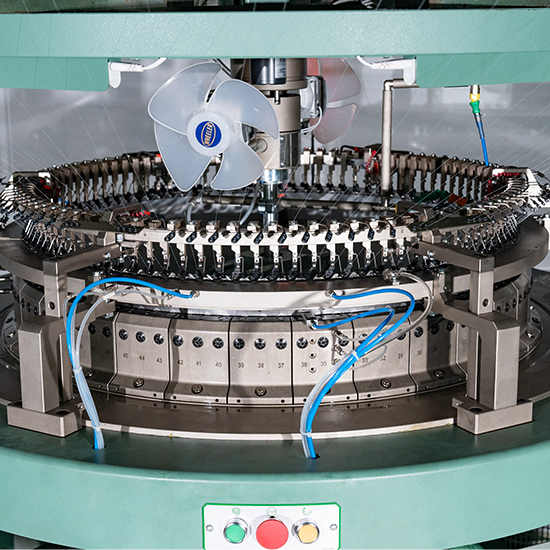

Products Features

1. High performance

2. Open-width speed parameters can reach 960(30rpm at 32”)

3. Most of the structure and main parts are produced by advanced processing equipment, which ensures precision and accuracy.

4. The frame design has been improved, and the steel with a particular angle is used to improve the strength and hardness of the main structure of the machine and keep the machine stable.

5. The three-axis linkage transmission system is adopted to ensure stability and accuracy during high-speed operation.

6. Imported gears and transmission systems are used, and the parts are high quality.

7. Yarn feeding ring: The whole and individually adjustable yarn feeding ring is adopted to improve the convenience of operation.

8. Double steel wire runway: The machine runs smoothly and reduces friction caused by running.

Fabric Sample

|

|

Production example

SJ3.0 for 32 inches, open width, and 28rpm [unfinished,85%]

|

Structure

|

Gauges (E)

|

Yarn

|

Weight (g/m2) |

Production kg/h

|

|

Single jersey |

28 |

Cotton Nm 30/1Ne |

125 |

24 |

Technical details

|

Type |

SJ3.0 |

|

Diameter [inch] |

26” - 42” |

|

No. Of feeders |

78F - 126F [3 feeds per inch ] (Example: 32” 96F) |

|

Speed factor [max] |

960 (Example: 30rpm at 32” ) |

|

Gauges [E] |

14GG-44GG |

Available frames

|

Tubular frame |

Open width frame |

||

|

Standard tubular frame

|

Giant tubular frame

|

Standard Open width frame

|

Giant open-width frame

|

|

Frame For 550 mm Fabric rolls

|

Frame for 680mm fabric rolls |

Frame for 330bric rolls

|

Frame for 680mm fabric rolls

|

General supplier

General supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram