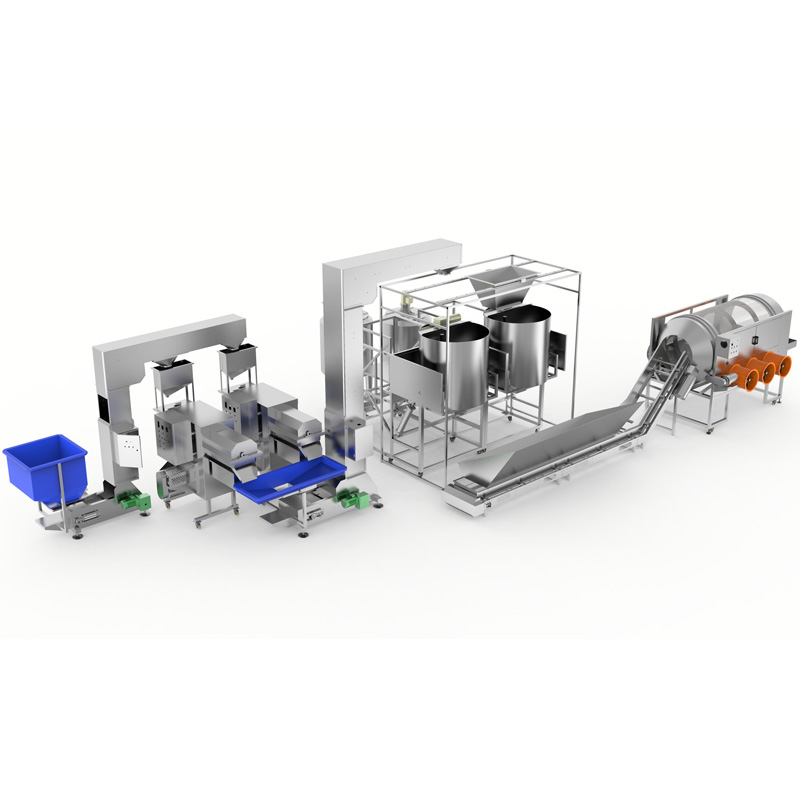

Industrial Hot Air Popper and Caramelizer Production Line Popcorn Production and Flavoring Line

1. Description

Support to add more popcorn machines and caramelizers directly to enlarge the capacity, this line is fully automatic for popcorn production and coating. It is cost-effective, suitable for popcorn factory who need 180-250kg/h output and will enlarge their output in the future.

2. Basic Parameters

|

Brand

|

XFD | Quality | High guarantee |

| MOQ | 1 Set | Technique | Hot air popcorn machine |

| Certification | CE, ISO 9001 | Main Material | USU 304 stainless steel |

| Condition | New | Application | Popcorn production |

| Warranty Time | 1 year | Type | Automatic |

3. Details and Features

* Modularization design, easy to maintain and replace.

* Equipped with an automatic alarm system, an adjustable digital display and control for precise temperature settings and measuring actual product temperature.

* High quality spare parts from World-famous Brand ABB, SIEMENS and DELTA,ensure the safe stable operation and longer working life.

* 304 USU Stainless steel for the whole line.

4. Structure and Characteristic

| NO. | ITEM | PICTURE | TECHNICAL PARAMETERS | UNIT | CHARACTERISTICS |

| 1 | Corn Feeding Machine |

|

Function | 1 | One Corn Feeding Machine with Two Feeding Hoppers, applied to Optic Sensor, high cost effective, and hidden circuit, safer and easier to clean. |

| Convey the raw corns into the hot air popcorn machine. | |||||

| Technical parameter | |||||

| Size: 3732*890*2650mm | |||||

| 2 | Hot Air Popcorn Machine |

|

Function | 2 | Easy to adjust production capacity with Two Hot air Popcorn Machine, Besides, the most important part is this machine comes with cooling and filtering popcorn function, economizing on electricity. |

| Popping the raw corns into popcorn with hot air. | |||||

| Technical parameter | |||||

| Capacity: 60~90kg/h | |||||

| Size: 2190*1029*2135mm | |||||

| 3 | Popcorn Feeding Machine |

|

Function | 1 | Hidden convey to protect popcorn from dust. Hidden circuit, safer and easier to clean. |

| Convey the pocorn into the popcorn feeding bin. | |||||

| Technical parameter | |||||

| Size: 4028*711*3800 mm | |||||

| 4 | Pre-melting Tank |

|

Function | 2 | Easy to inhale materials ( caramel, chocolate…) with Fully enclosed pre-melting tank, safter and health. |

| Melting the flavoring materials when the coating machine is working, such as chocolate, cheese, caramel, etc. | |||||

| Technical parameter | |||||

| Size: 1000*1000*2000mm | |||||

| 5 | Active Feeding Bin |

|

Function | 1 | Equipped with high quality and accurate senors on location, volume and so on. It could be lengthened according to your needs. |

| Through the sliding track, feeding the popcorn into the caramelizer. | |||||

| Technical parameter | |||||

| Size: 3000*1560*3030mm | |||||

| 6 | Large Size Caramelizer |

|

Function | 2 | Equipped with automatic kettle-dumping and self-clean system. Energy saving. |

| Coating different flavored popcorn with chocolate, cheese, caramel, etc. | |||||

| Technical parameter | |||||

| Size: 2659*900*2330mm | |||||

| 7 | Z Type Elevator |

|

Function | 1 | Easy to clean. |

| Cooling and conveying the flavored popcorn into the cooling and separating machine. | |||||

| Technical parameter | |||||

| Size: 5462*1178*1505mm | |||||

| 8 | Cooling and Separating Machine |

|

Function | 1 | Easy to clean, high capacity. |

| Cooling, filtering and separating the finished popcorn. | |||||

| Technical parameter | |||||

| Dimension:3500*2100*1950mm |

You can choose any part from 1 to 8 according to your needs. For more details, please feel free to contact us soon.

5. Why Choose Us?

* Factory sale directly with competitive price

* Flexible payment terms including T/T,L/C and so on

* Fast delivery within 15 days receiving the deposit

* Professional sales team,quality inspection and report, maritime logistics guidance

* After-sale services:video technical support, 24 h online support

General supplier

General supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram