Features

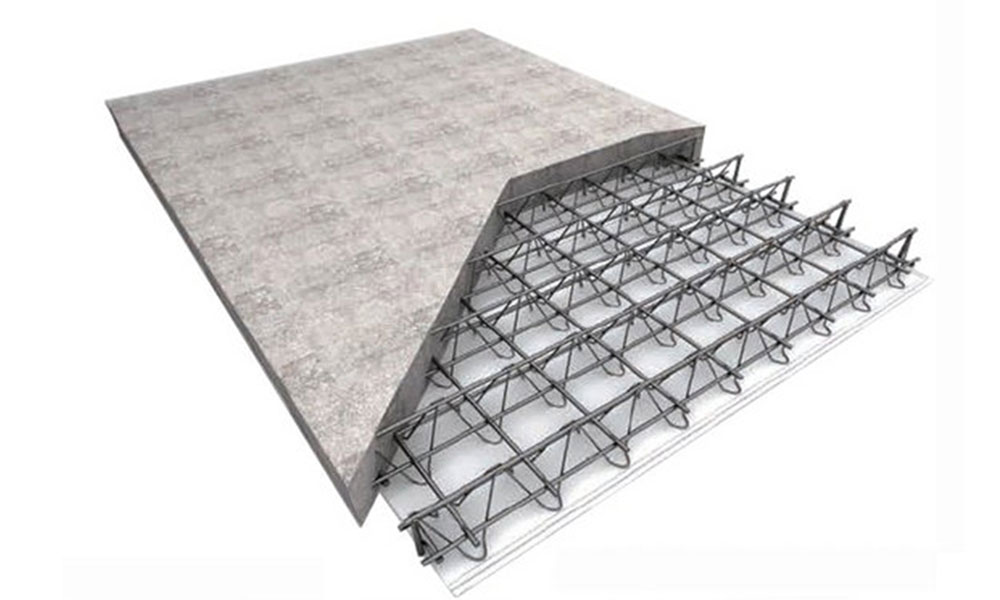

☆ Steel bars are evenly arranged and the bearing mode is reasonable, which greatly reduces the engineering quantity of temporary support;

☆ The double edge fold design can effectively ensure the quality of the engineering;

☆ It can shorten the time by reducing 60% to 70% work load of binding steel bars;

☆It has the same mechanical properties and fire resistance as that of traditional cast-in-place floors. Because the bottom mould does not join in the load-baring, it is unnecessary to consider fire proof and anti-corrosion;

Applications

The steel bar truss deck is widely applied for the mezzanine construction of commercial and civilian buildings, such as factories, hospitals, gymnasiums, schools, bridge projects and residential buildings.

Specifications

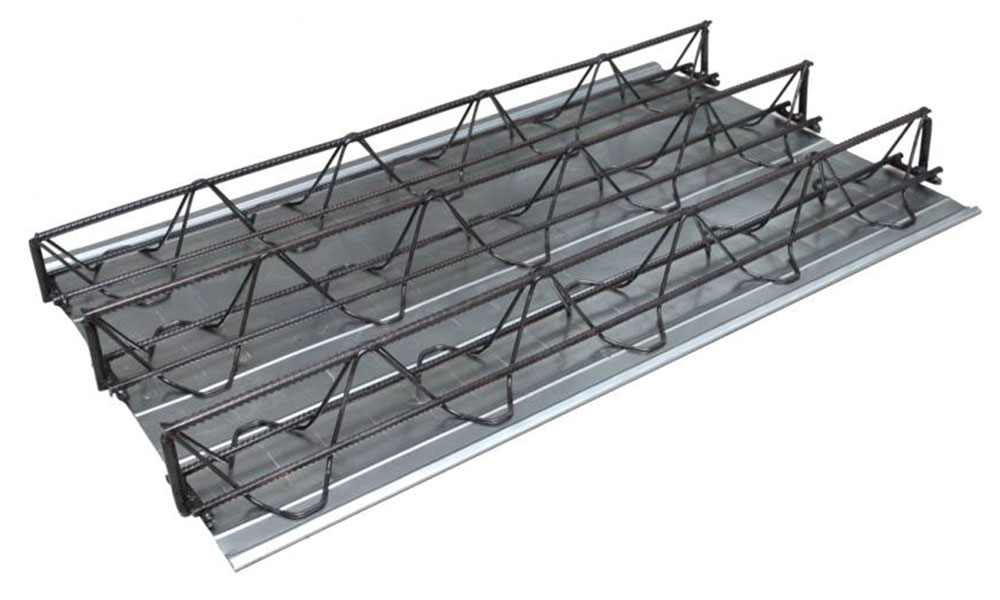

Product component | Top bars,Bottom bars,Lattice,Bracket vertical bars,Base sheet | |

Product parameters | Top bars & Bottom bars:Hot-rolled coiled steel bar H R B 4 0 0E ,H P B 3 0 0 ; | |

Lattice:Hot-rolled coiled steel bar H R B 4 0 0 or Cold rolled round bar with equivalent performance C R B 5 5 0 | ||

Bracket vertical bars:Hot-rolled coiled steel bar H R B 4 0 0 ,H P B 3 0 0 ; | ||

Bottom sheets: Q 2 3 5 cold rolled steel sheet;

| ||

Product specs | Truss deck | Specs |

Bottom sheet width(mm) | 600mm | |

Length(m) | 1.0-11.9 | |

Floor thickness(mm) | 100-300 | |

Steel truss height(mm) | 70-270 | |

Concrete cover thickness(mm) | 15(Top&Bottom of truss is 15mm) | |

Base sheet thickness | 0.50mm~0.80mm | |

Reinforced concrete slab production & installation video

If you need more technical data for reference,please download our catalog.Thank you.

Pictures

Packing & Delivery:

☆ Packing:

Seaworthy packing standards.

☆ Delivery:

Delivery time for small order with stock material: 7-10 days ;

Delivery time for special requirement,coating types and thickness: 15-25 days ;

Delivery term: FOB/CIF/CFR/DDP is available;

We can find good forwarder for customers or accept appointed forwarder from customers.

Gold supplier

Gold supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram