Aluminum standing seam metal roofing panel features

☆ No exposed fasteners, that means it won't exposed to UV, moisture, wind and other elements taht cause fastener to wear or fail over time. Meanwhile, it doesn't need punch holes so that protect the panels. So it is good to corrosion resistant.

☆ Weatherproof, this standing seam roof system will not leak or fail during specific weather conditions,

☆ Longevity, standing seam roof panel lasts significantly longer and requires less maintenance, especially when compared to other other roofing types.

☆ Applicable to different architectural styles, standing seam systems can be used on structures with many different complex designs, that is one reason that architects are choose this panel more often.

Standing seam roof sheet assemble types

☆ Type 01:

☆ Type 02:

☆ Type 03:

Aluminum roof plate applications

It is widely used in residential houses, villas, resorts, stations, airport terminals, upscale hotels, clubs, exhibition halls, etc.

Standing seam roofing sheets specifications

|

Model NO. : |

YX 65-400/420/430 |

|

Rib height : |

65 mm |

|

Rib distance : |

N/A |

|

Modular width : |

400 / 420 / 430 mm |

|

Feeding width : |

596 / 616 / 626 mm |

|

Available thickness : |

0.30 - 0.75 mm for steel sheets; 0.50 - 1.20 mm for aluminum sheets and Al-Mg-Mn alloy metal sheets |

|

Available length : |

20FT container: ≤ 5.95m |

|

Available material : |

PPGI/ PPGL/ Aluminum sheets/ Al-Mg-Mn alloy metal sheets |

|

Surface treatment : |

Original pre-painted color |

|

Coating type : |

PE, PVDF, HDP, SMP, etc. |

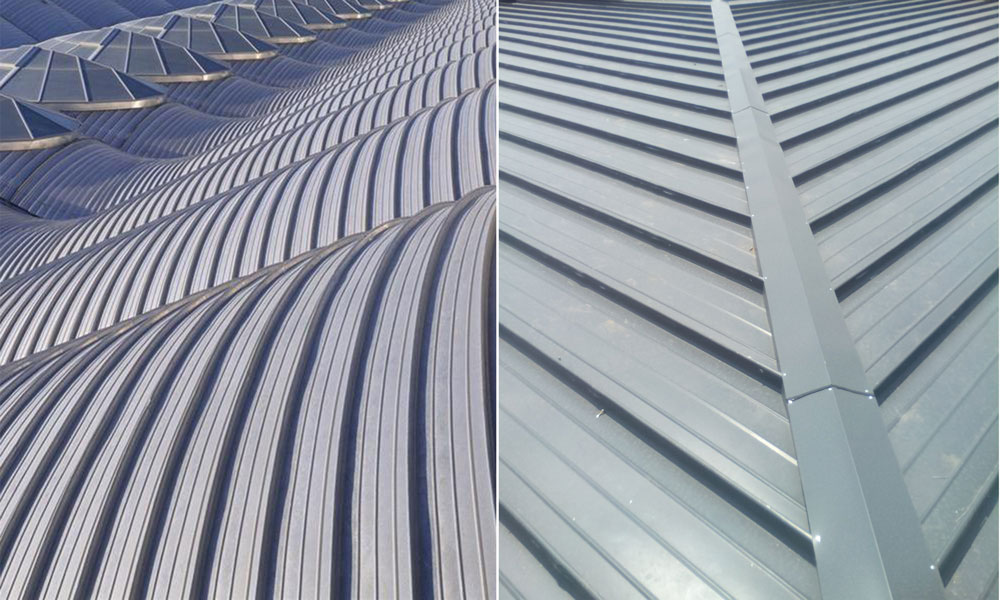

High rib standing seam sheets renderings

Packing & Delivery:

☆ Packing:

Seaworthy packing standards:

Premium packing:

Packed with steel box,in order to protect the panels in good status before installation.

☆ Delivery:

Delivery time for regular colors,coating types and thickness: 7-10 days ;

Delivery time for special colors,coating types and thickness: 15-25 days ;

Delivery term: FOB/CIF/CFR/DDP is available;

We can find good forwarder for customer or accept appointed forwarder from customers.

Gold supplier

Gold supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram