Wall sandwich board characteristics

☆ Eco-friendly core material can save natural resources and make the product an ecological building material;

☆ With PU sealing end and glass wool/rockwool core fulfils all the requirements for non-combustible building materials;

☆ Easier and faster installation,it can save labor cost, especially for longer panels;

☆ It is possible to reach fire-safety, acoustic and thermal requirements at once without any visual impact.

Sandwich panel walls types introduction

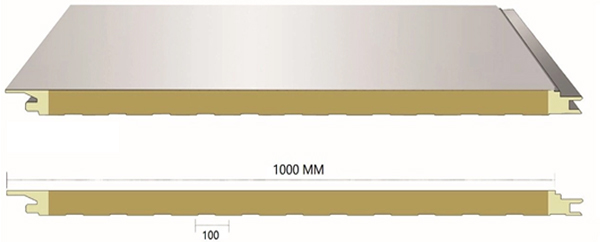

Panel effective width: 1000mm

Thickness available: 50/ 75/ 100/ 120/ 150/ 200mm

Panel joint: Concealed hidden screws type,can be with or without decorative seam

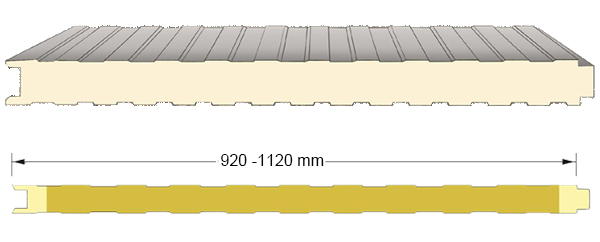

Panel effective width: 930/ 1000/ 1120mm

Thickness available: 30/ 35/ 40/ 50/ 60/ 75/ 100/ 150/ 200/ 250mm

Panel joint:Visible joint (tongue and groove) type

Sandwich panel texture

These two panel types have wide ribs,mircro ribs and flat texture for choosing.

Steel wall sandwich panels material description

|

Insulation core material : |

PUR sealing rockwool/glass wool |

|

Density : |

38 ~ 42 KG/M³ for PU; 80 ~ 150 KG/M³ for Rockwool; 48 ~ 68 KG/M³ for glass wool. |

|

Steel sheet thickness : |

0.40 ~ 0.75 mm |

|

Stainless steel sheet thickness : |

0.40 ~ 0.70 mm |

|

Al-Mg-Mn alloy metal thickness : |

0.70 ~1.20 mm |

Sandwich panel wall application

This quality wall sandwich panels types have great potential, and most of metal buildings with artistic features will choose this metal panels.If you have any project need special designs,we can have our engineers to support your design work.

Concealed hidden screws type wall panel rendering

Visible joint (tongue and groove) type rendering

Packing & Delivery:

☆ Packing:

1)Number of panels per packages for your reference:

|

Panel thickness/mm |

Panels per package/PCs |

Remark |

|

50 |

22 |

Standard package weight:3-5/ton for each package |

|

75 |

15 |

|

|

100 |

11 |

|

|

150 |

7 |

|

|

200 |

6 |

PVC on both sides to protect the roof panel surfaces;

Packed with kraft paper to protect the panel ends;

Put EPS foam on the each space to keep the panels from squeezing each other.

If you have special requirement,please feel free to discuss with us.This is to make us improved,and protect your goods well.

☆ Delivery:

Delivery time for regular colors,coating types and thickness: 7-10 days ;

Delivery time for special colors,coating types and thickness: 15-25 days ;

Delivery term: FOB/CIF/CFR/DDP is available;

We can find good forwarder for customer or accept appointed forwarder from customers.

Gold supplier

Gold supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram