Features

1. To meet the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short time, and can use multiple floors to lay profiled steel plates and layered concrete slabs.

2. In the use phase, the floor bearing slab is used as the tensile steel bar of the concrete floor slab, which also improves the rigidity of the floor slab and saves the amount of steel and concrete.

3. The surface embossing of the profiled slab creates the binding force between the floor deck and the concrete to form a whole, with stiffening ribs, so that the floor deck system has high bearing capacity.

4. Under the cantilever condition, the floor deck is only used as a permanent template. The length of the cantilever can be determined according to the section characteristics of the floor deck. In order to prevent the cracking of the overhanging plate, it is necessary to equip the support with negative ribs according to the design of the structural engineer.

5. The floor deck of our company has passed the fire resistance limit test of the National Fixed Fire Extinguishing System and the Quality Inspection Center for Fire-resistant Components. As a composite floor deck, it is don't require to spraying fireproof material, so the project cost is greatly reduced.

Specification

| Model NO. | YXB48-200-600 |

| Rib height | 48 mm |

| Rib distance | 200 mm |

| Modular width | 600 mm |

| Feeding width | 1000 mm |

| Material | Galvanized / Galvalume steel |

| Thickness | 0.75 ~ 1.5 mm |

| Steel material | High strength galvanized steel sheets |

| Material standards | Q235, Q345, Q355, G550 |

| Zinc coating | 120 ~ 275 g/㎡ |

| Length | Max 5.95m for 20 FT container |

| Max 11.95m for 40 FT container |

Technical data (for reference)

| Thickness (mm) | Yield strength (Mpa) | Weight (kg /㎡) | I (cm4 /m) | I (cm3 /m) |

| 0.8 | 235 | 10.93 | 43.24 | 12.35 |

| 0.9 | 235 | 12.11 | 48.65 | 13.90 |

| 1.0 | 235 | 13.54 | 54.05 | 15.44 |

| 1.2 | 235 | 16.16 | 64.86 | 18.53 |

Span table for reference (Q235)

| Slap thickness (mm) | Sheet thickness (mm) | Single span (m) | Double spans (m) |

| 110 | 0.8 | 1.91 | 1.91 |

| 0.9 | 2.03 | 2.03 | |

| 1.0 | 2.13 | 2.13 | |

| 1.2 | 2.33 | 2.33 | |

| 120 | 0.8 | 1.86 | 1.86 |

| 0.9 | 1.98 | 1.98 | |

| 1.0 | 2.08 | 2.08 | |

| 1.2 | 2.27 | 2.27 | |

| 130 | 0.8 | 1.82 | 1.82 |

| 0.9 | 1.93 | 1.93 | |

| 1.0 | 2.03 | 2.03 | |

| 1.2 | 2.22 | 2.22 | |

| 140 | 0.8 | 1.78 | 1.78 |

| 0.9 | 1.88 | 1.88 | |

| 1.0 | 1.98 | 1.98 | |

| 1.2 | 2.16 | 2.16 | |

| 160 | 0.8 | 1.70 | 1.70 |

| 0.9 | 1.80 | 1.80 | |

| 1.0 | 1.89 | 1.89 | |

| 1.2 | 2.07 | 2.07 |

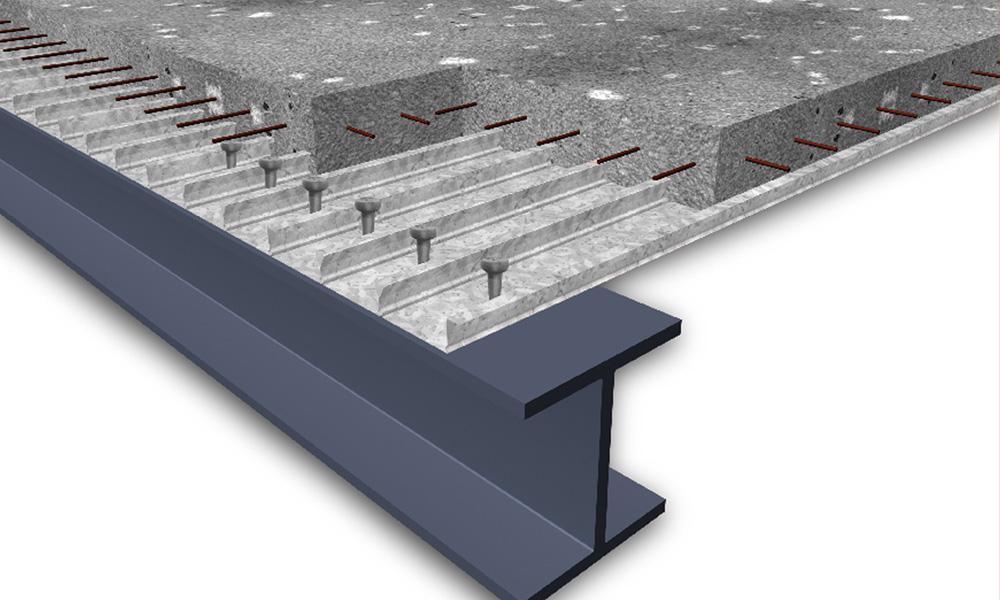

Product picture

Packing & Delivery

☆ Packing:

Seaworthy packing standards:

Premium packing:

Packed with steel box,in order to protect the panels in good status before installation.

☆ Delivery:

Delivery time for regular colors,coating types and thickness: 7-10 days ;

Delivery time for special colors,coating types and thickness: 15-25 days ;

Delivery term: FOB/CIF/CFR/DDP is available;

We can find good forwarder for customer or accept appointed forwarder from customers.

Linkedin

Linkedin  Tik Tok

Tik Tok  Facebook

Facebook  YouTube

YouTube  Pinterest

Pinterest